It's #FreeCADFriday once again~

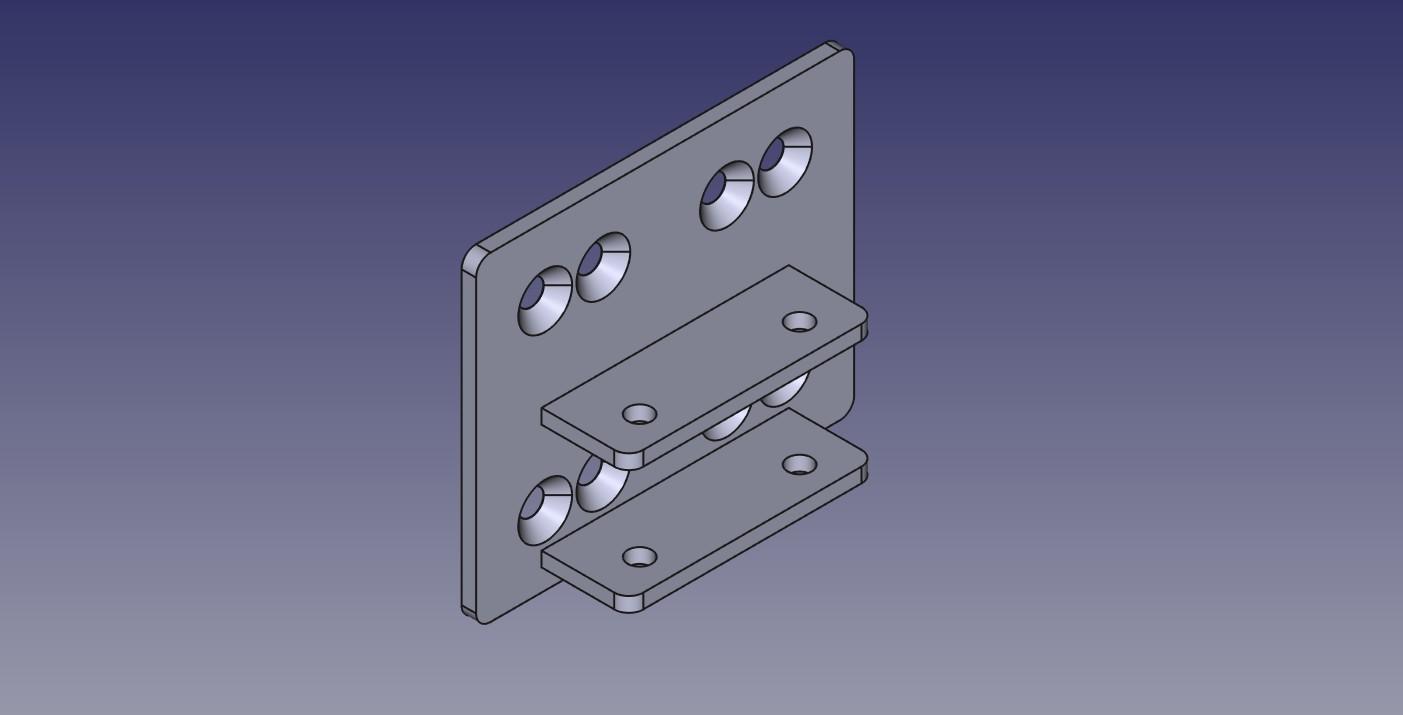

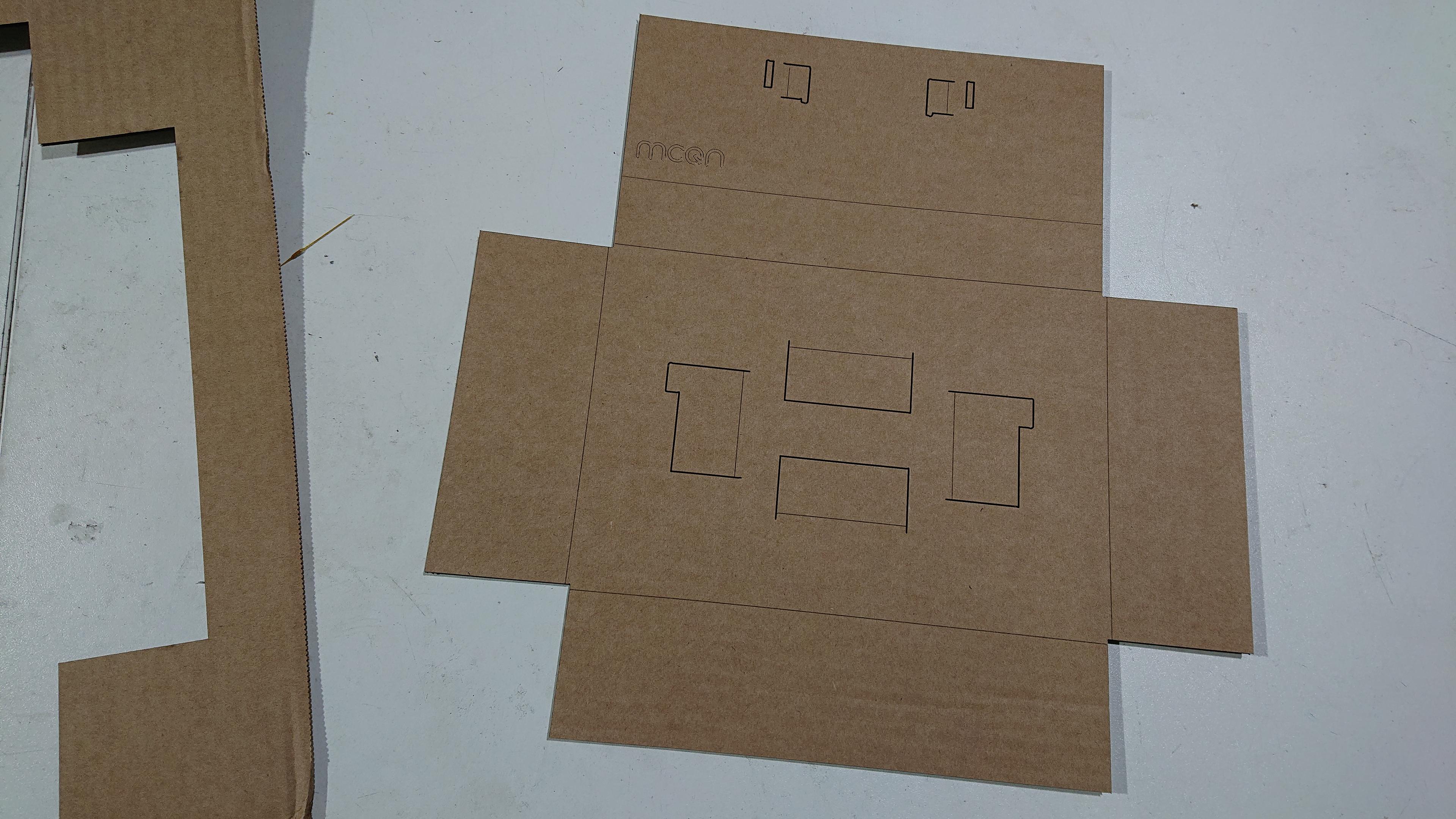

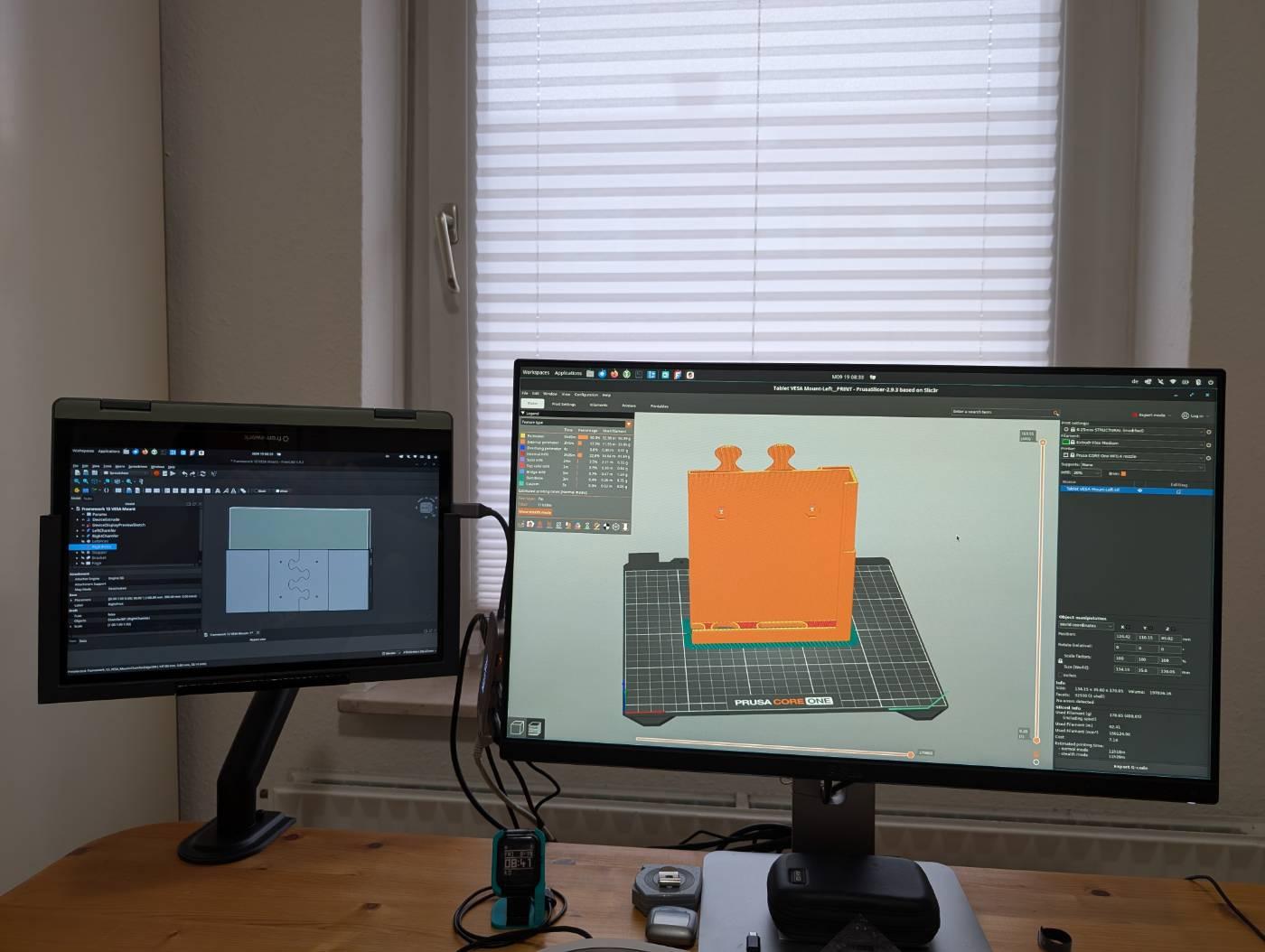

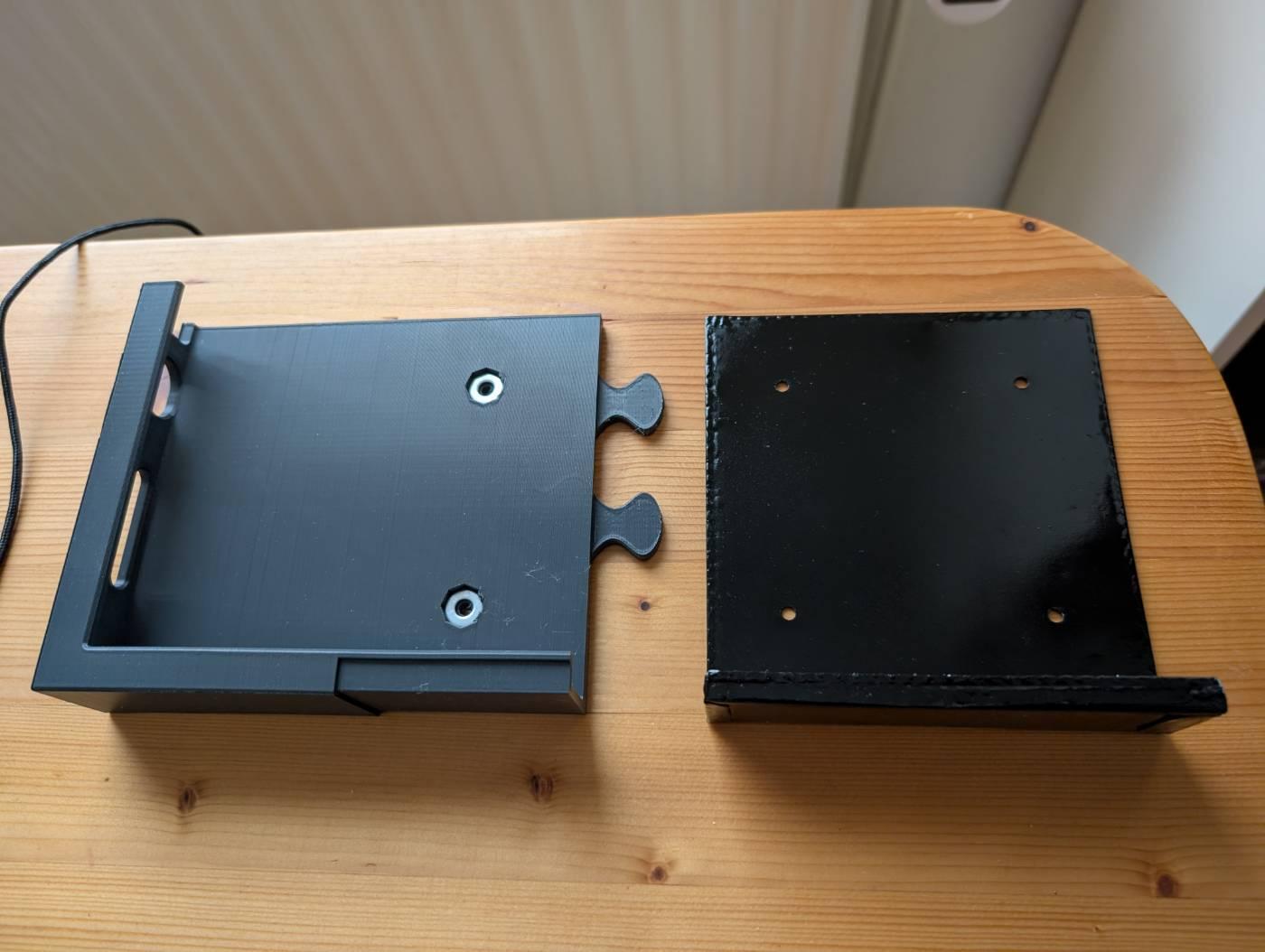

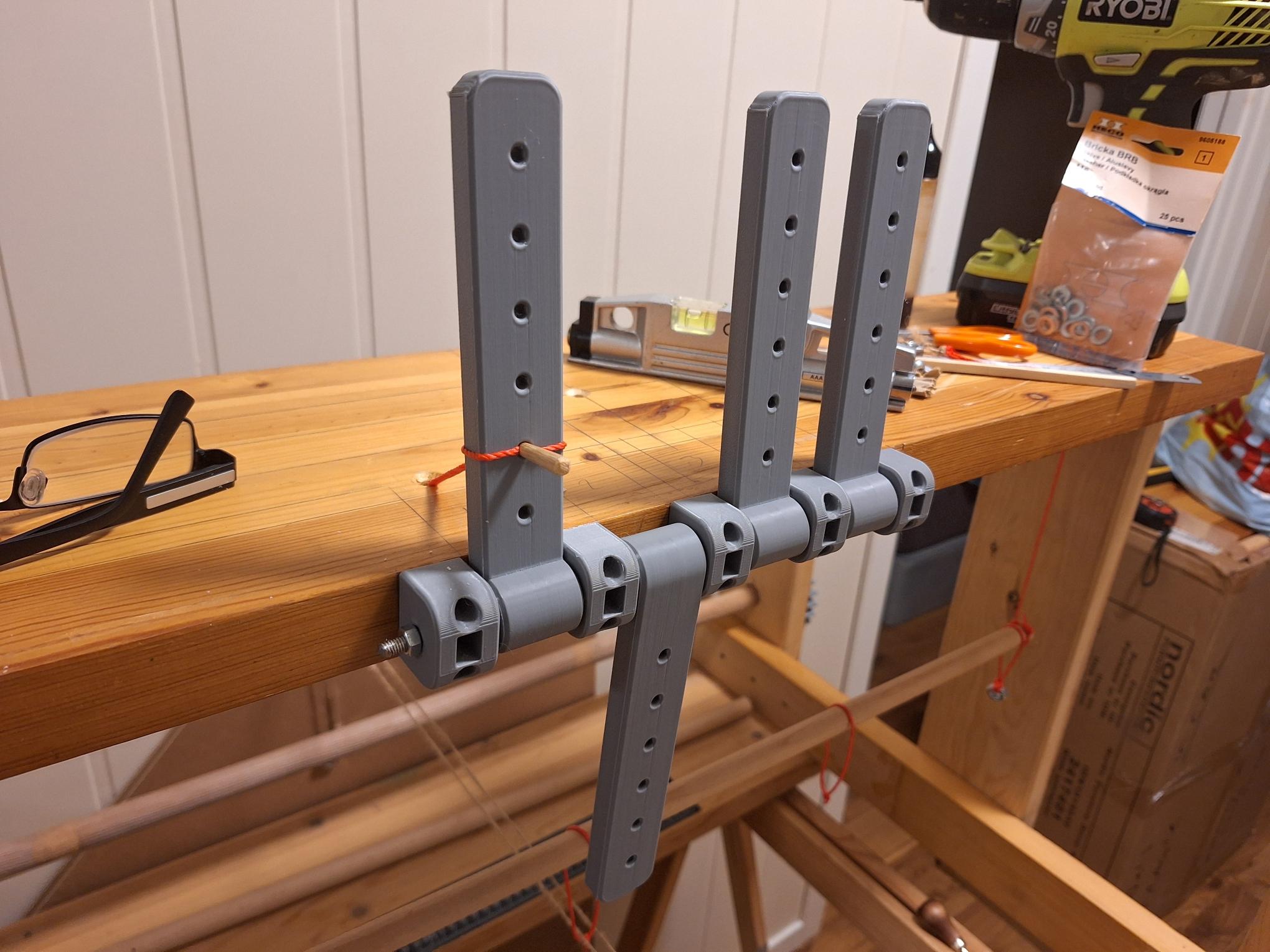

Did you know you can use @FreeCAD to design computer networks? Ok, it's just a coupler for some @mikrotik devices to put two 10" units in a single 19" U.

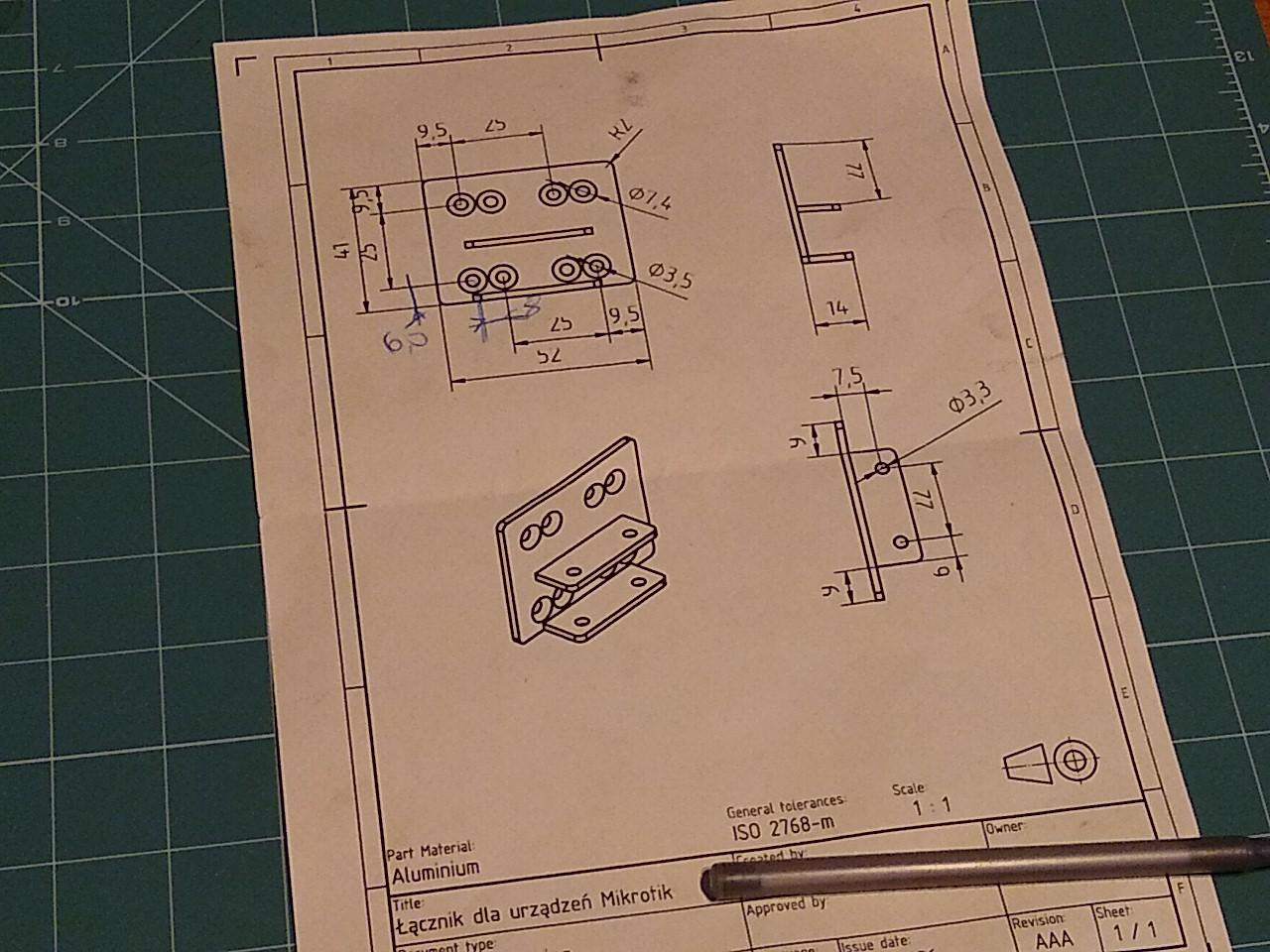

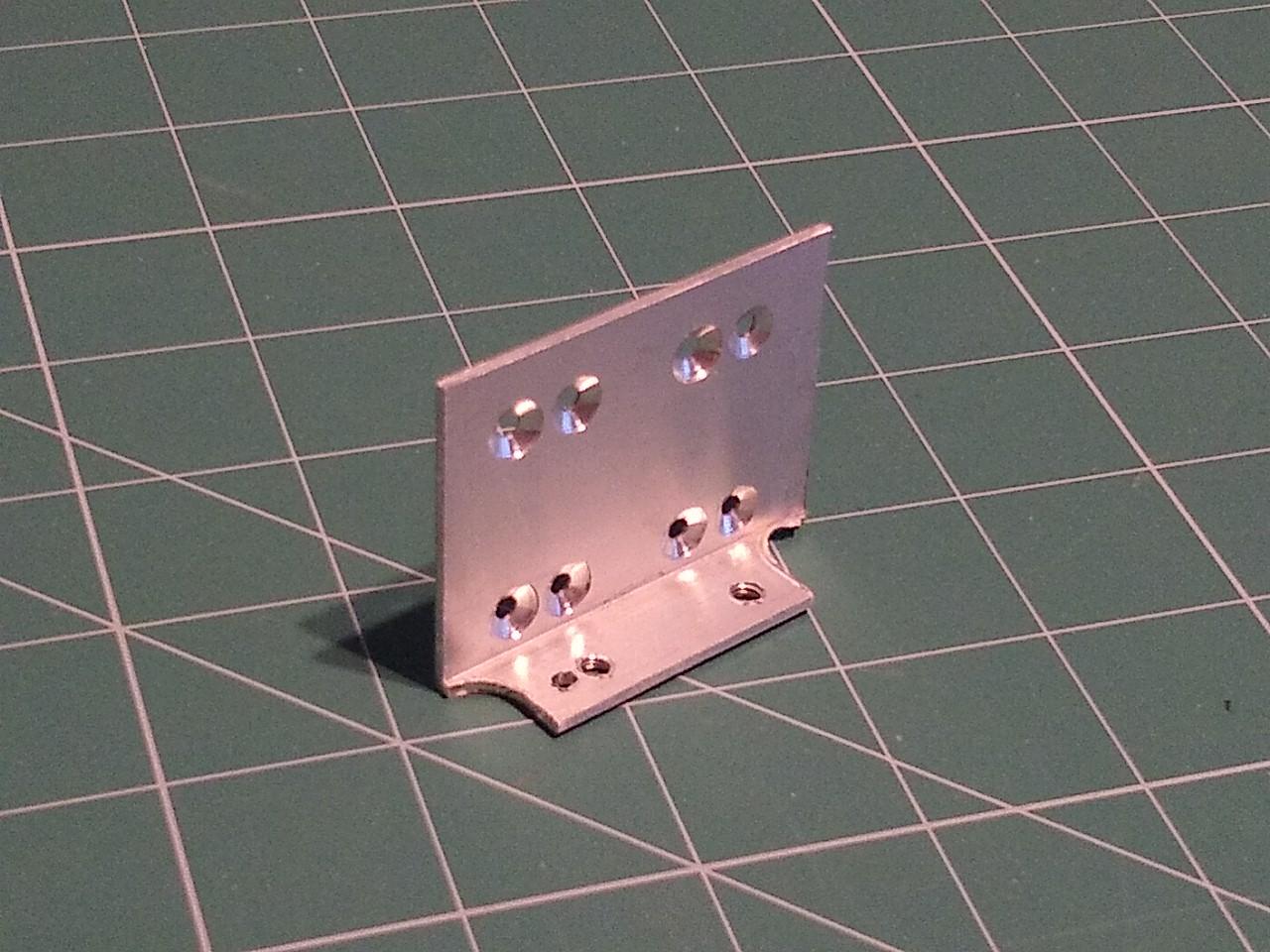

The basic option to make this part is to cut a 52 mm long piece of aluminium angle. Drill 6 holes and cut the sides of angle to be 41 mm and 14 mm.

I'd recommend mounting devices connected with a this DIY part above a patch panel that can in part support their weight.

The part works left AND right.