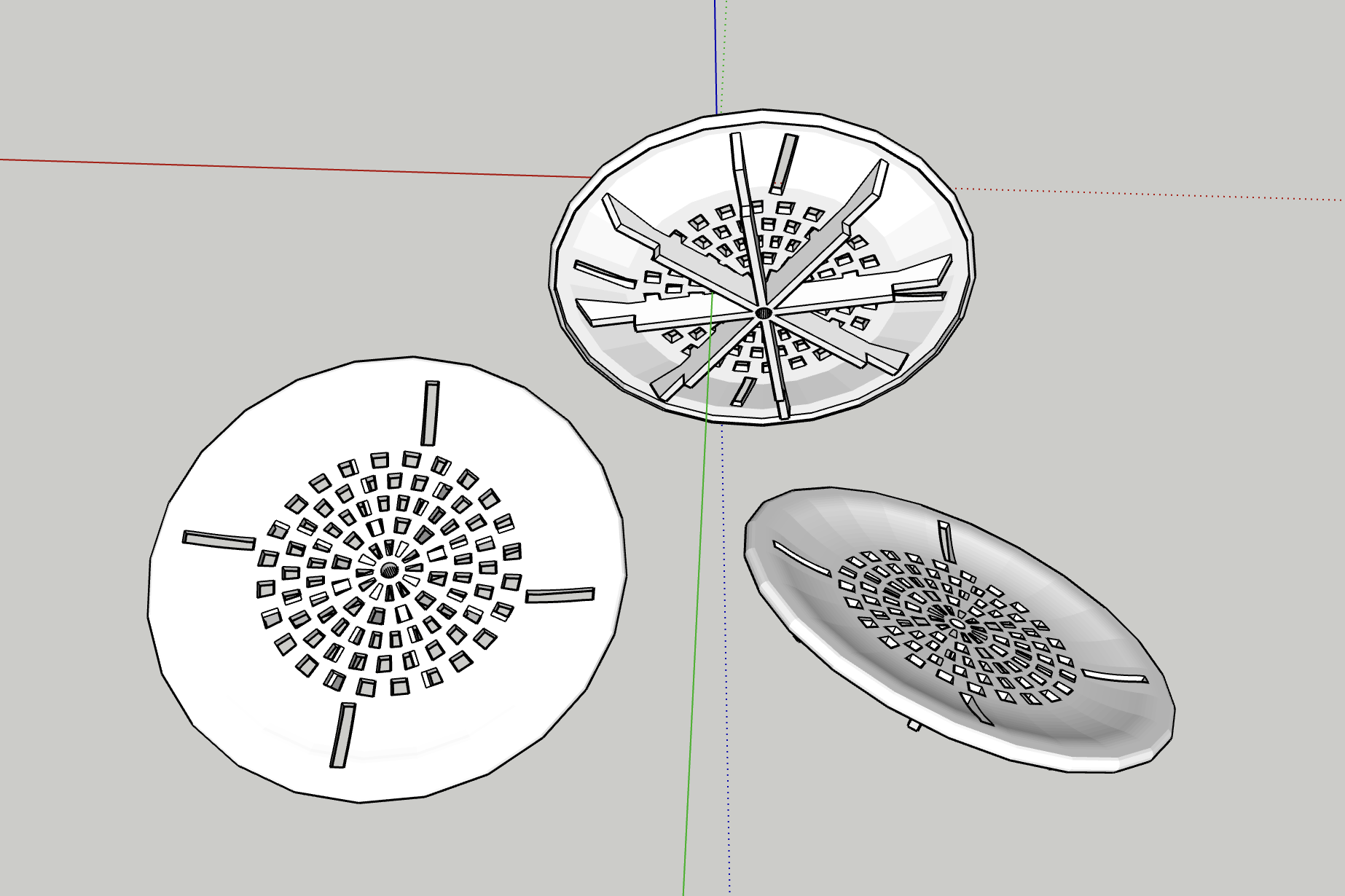

An unglamorous #3Dprinting / #CAD project I'm nonetheless very pleased with. I designed a new drain cover for my shower.

An unglamorous #3Dprinting / #CAD project I'm nonetheless very pleased with. I designed a new drain cover for my shower.

Taking the opportunity to finally publish some of my recent 3d print designs.

Starting off with this little holder for a Wera Tool-Check toolkit.

https://www.printables.com/model/1576168-wera-tool-check-holder

Die Jugend von heute .... trägt Bücher am Ohr. 😍 #Heartstopper #AliceOseman 🌈 #Making

Die Jugend von heute .... trägt Bücher am Ohr. 😍 #Heartstopper #AliceOseman 🌈 #Making

'Askers' vs. 'Guessers' (2010)

https://www.theatlantic.com/national/2010/05/askers-vs-guessers/340891/

#HackerNews #Askers #Guessers #2010 #Communication #Skills #Decision #Making #Psychology

Just tried a new technique I've never tried before, and it worked so much better than I could have ever hoped. Not gonna say much more until I write the blog post for this project. But am very happy with the result.

Folks~ I've started a new thing. It's intimidating, but I've been threatening to do this for a while. For now the shape is largely amorphous, but hoping with practice I'll find some grooves. If you are so inclined, please subscribe. Aiming to drop new long-form monthly with shorter pieces every week. What's it about? Read on... https://lnkd.in/dXVuJ3YD #design #designprocess #making #starting #process #wip

Please enjoy this ridiculous thing I made for my new bathroom. My self-assigned brief was:

- Store bulk toilet roll in that convenient space over the cistern,

- In a way where you can easily grab a new roll from sitting on the toilet,

- Without risk of toilet roll avalanches when you do so.

It's a dispenser loaded from top, with a sloped bottom that leads down to a hole at the bottom corner to take one roll at a time.

It is not neat or polished but it DOES work.

Please enjoy this ridiculous thing I made for my new bathroom. My self-assigned brief was:

- Store bulk toilet roll in that convenient space over the cistern,

- In a way where you can easily grab a new roll from sitting on the toilet,

- Without risk of toilet roll avalanches when you do so.

It's a dispenser loaded from top, with a sloped bottom that leads down to a hole at the bottom corner to take one roll at a time.

It is not neat or polished but it DOES work.

After working on it for almost 9 months. I recently finished my hardest build yet. I've written a blog post about it. (Warning, long). Grab a cuppa and have a read.

#Making #MakersHour #Machining #WoodWork #3DPrinting #OpenSCAD

After working on it for almost 9 months. I recently finished my hardest build yet. I've written a blog post about it. (Warning, long). Grab a cuppa and have a read.

#Making #MakersHour #Machining #WoodWork #3DPrinting #OpenSCAD

Something from nothing

I am not a talented person, I've never been called "gifted" or anything like that. Anything I can do, anything I achieved took a lot of work and stubbornness to achieve. Don't get me wrong. I am not saying that I'm "selfmade" and that my position in society, my access to resources, etc. had nothing to do with it - quite the opposite. As a white heterosexual cis-man in Germany I have started live on easy mode. But I do not come from a wealthy background or one with large networks and access to […]

$5 whale listening hydrophone making workshop

https://exclav.es/2025/08/03/dinacon-2025-passive-acoustic-listening/

#HackerNews #$5 #whale #listening #hydrophone #making #workshop #acoustic #marine #life #DIY #ocean #conservation

Coding is like taking a lump of clay and slowly working it into the thing you want it to become. It is this process, and your intimacy with the medium and the materials you’re shaping, that teaches you about what you’re making – its qualities, tolerances, and limits – even as you make it. You know the least about what you’re making the moment before you actually start making it. That’s when you think you know what you want to make. The process, which is an iterative one, is what leads you towards understanding what you actually want to make, whether you were aware of it or not at the beginning. Design is not merely about solving problems; it’s about discovering what the right problem to solve is and then solving it. Too often we fail not because we didn’t solve a problem well but because we solved the wrong problem.

When you skip the process of creation you trade the thing you could have learned to make for the simulacrum of the thing you thought you wanted to make. Being handed a baked and glazed artefact that approximates what you thought you wanted to make removes the very human element of discovery and learning that’s at the heart of any authentic practice of creation. Where you know everything about the thing you shaped into being from when it was just a lump of clay, you know nothing about the image of the thing you received for your penny from the vending machine.

#AI#VibeCoding #design #development #making #creation #artiface #craft #coding #programming #technology #humanity

Something from nothing

I am not a talented person, I've never been called "gifted" or anything like that. Anything I can do, anything I achieved took a lot of work and stubbornness to achieve. Don't get me wrong. I am not saying that I'm "selfmade" and that my position in society, my access to resources, etc. had nothing to do with it - quite the opposite. As a white heterosexual cis-man in Germany I have started live on easy mode. But I do not come from a wealthy background or one with large networks and access to […]

Making tiny 0.1cc two stroke engine from scratch

https://youtu.be/nKVq9u52A-c?si=KVY6AK7tsudqnbJN

#HackerNews #Making #tiny #engines #DIY #two-stroke #engineering #innovation