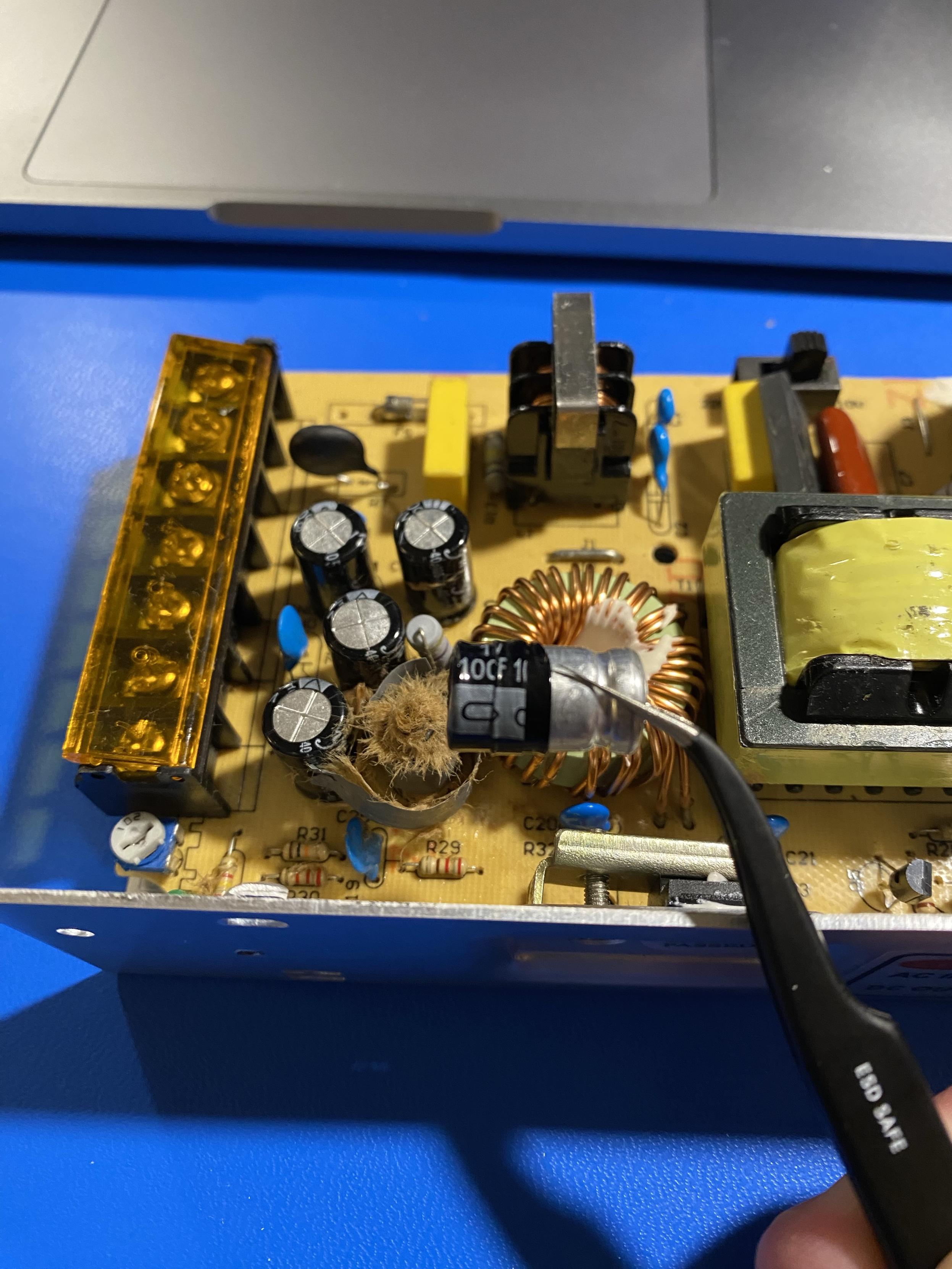

Well, there’s yr problem

Well, there’s yr problem

unpleasant

Well, there’s yr problem

Repair Day is tomorrow at @xHain_hackspace Come work on your broken music gear or prototypes with help from volunteers and equipment from xHain.

https://codeberg.org/gndbuzz/gists/src/branch/main/20260222-repair-day-xhain

#repaircafe #berlin #makerspace #hackerspace #electronics #diyelectronics #diymusic

Repair Day is tomorrow at @xHain_hackspace Come work on your broken music gear or prototypes with help from volunteers and equipment from xHain.

https://codeberg.org/gndbuzz/gists/src/branch/main/20260222-repair-day-xhain

#repaircafe #berlin #makerspace #hackerspace #electronics #diyelectronics #diymusic

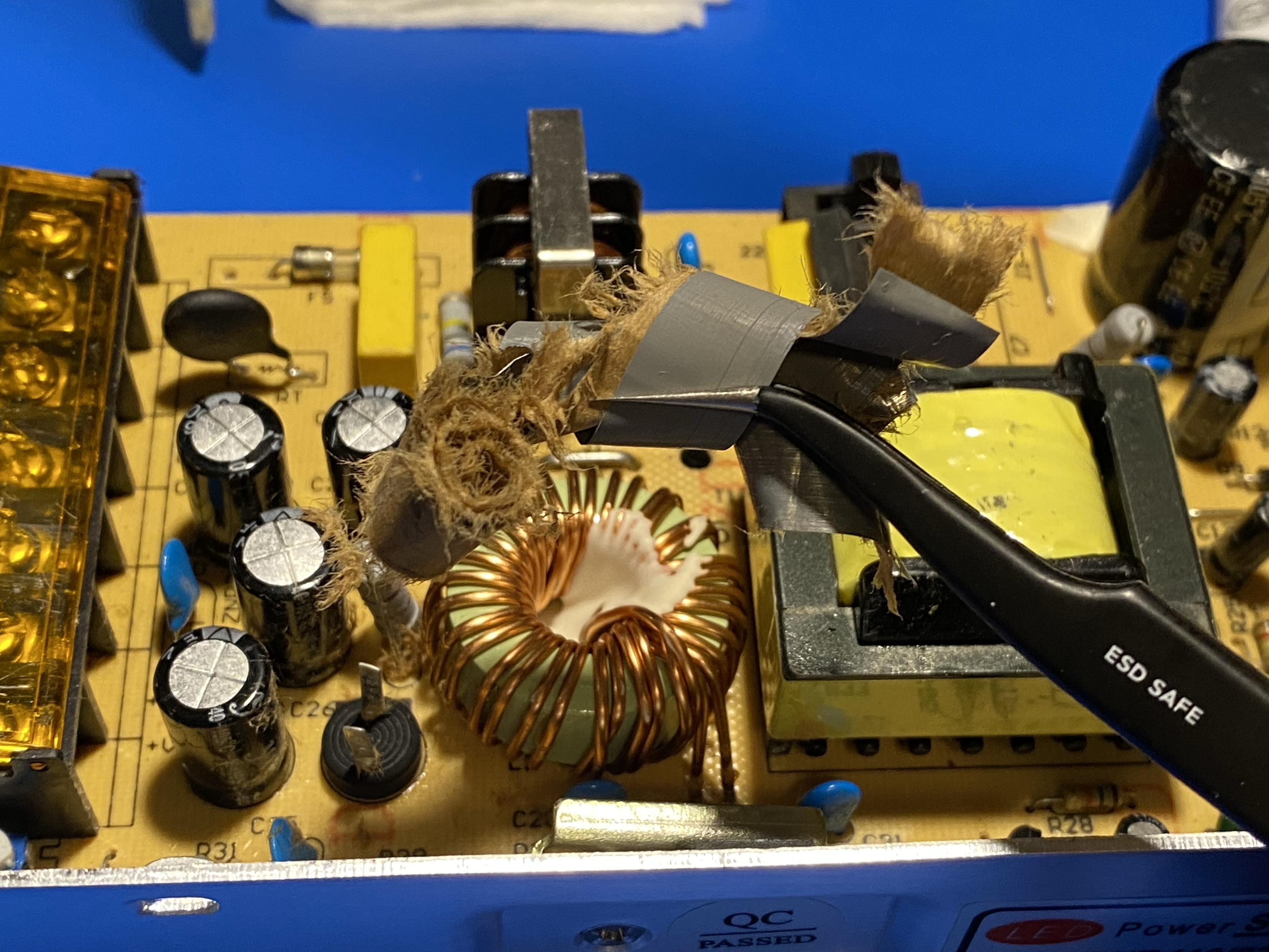

What to do when a Li-ion #battery smells of fruit?

Run away. Throw it away. Duck and cover.

Lithium fire is no fun!

Single-use vapes should be banned, but while they aren't, I'll clean them up and put them to use.

Just the smells make it really confusing :S

The battery doesn't look bloated. Regardless, it is quarantined outside, in a concrete tiles area.

What to do when a Li-ion #battery smells of fruit?

Run away. Throw it away. Duck and cover.

Lithium fire is no fun!

Single-use vapes should be banned, but while they aren't, I'll clean them up and put them to use.

Just the smells make it really confusing :S

The battery doesn't look bloated. Regardless, it is quarantined outside, in a concrete tiles area.

After some extensive soldering time I've now got stock ready of all my expansions and peripherals for use with #RC2014 and compatible systems. All the info and to purchase please see: https://2014.samcoupe.com

- SID Soundchip Interface (6581 configuration in stock, use the famous #Commodore #C64 SID Soundchip with your RC setup, or use modern replacement such as ArmSID)

- Graphic OLED Interface (32x128 graphic display)

- ZX True Tone (ZXTT, for use with Ed Brindley's YM/AY soundcard so the soundchip is clocked exactly at the same frequency as the 128K #ZXSpectrum)

- SAA1099P Sound chip Interface (Use the 6 channel stereo sound chip, as used in the #SAMCoupe, in your RC setup)

- RC-ZX Bus Interface (Use RC2014 I/O peripherals on the #ZXSpectrum)

- RC-SAM Bus Interface (Use RC2014 I/O peripherals on the #SAMCoupe)

#retrocomputing #z80 #hardware #retrogaming #electronics #synth #demoscene

After some extensive soldering time I've now got stock ready of all my expansions and peripherals for use with #RC2014 and compatible systems. All the info and to purchase please see: https://2014.samcoupe.com

- SID Soundchip Interface (6581 configuration in stock, use the famous #Commodore #C64 SID Soundchip with your RC setup, or use modern replacement such as ArmSID)

- Graphic OLED Interface (32x128 graphic display)

- ZX True Tone (ZXTT, for use with Ed Brindley's YM/AY soundcard so the soundchip is clocked exactly at the same frequency as the 128K #ZXSpectrum)

- SAA1099P Sound chip Interface (Use the 6 channel stereo sound chip, as used in the #SAMCoupe, in your RC setup)

- RC-ZX Bus Interface (Use RC2014 I/O peripherals on the #ZXSpectrum)

- RC-SAM Bus Interface (Use RC2014 I/O peripherals on the #SAMCoupe)

#retrocomputing #z80 #hardware #retrogaming #electronics #synth #demoscene

Is there an #electronics community on here?

hi I’m Phos, an electrical engineer from Austria. I work on lots of things, but right now my main focus is pulsed power systems for electrical discharge machining

out lab is pretty decently equipped and we get up to lots of fun experiments

we also love helping people and contributing our time to open source projects

we also recently started making weekly update videos, as well as tutorials, both on YouTube and also Fedi

hi I’m Phos, an electrical engineer from Austria. I work on lots of things, but right now my main focus is pulsed power systems for electrical discharge machining

out lab is pretty decently equipped and we get up to lots of fun experiments

we also love helping people and contributing our time to open source projects

we also recently started making weekly update videos, as well as tutorials, both on YouTube and also Fedi

the #DirtCheapEmp page has a demo video now too https://blog.dirtcheaphackingtools.com/dirt-cheap-emp

#hacking #hackingtools #emfi #faultinjection #electronics #hardware #hardwarehacking

the #DirtCheapEmp page has a demo video now too https://blog.dirtcheaphackingtools.com/dirt-cheap-emp

#hacking #hackingtools #emfi #faultinjection #electronics #hardware #hardwarehacking

Is there an #electronics community on here?

The relentless surge in memory chip prices over the past few months has driven a vast divide between winners and losers in the stock market, and investors don’t see any end in sight. https://www.japantimes.co.jp/business/2026/02/10/tech/memory-chip-crunch-markets/?utm_medium=Social&utm_source=mastodon #business #tech #nintendo #apple #computers #chipmakers #tech #semiconductors #trade #electronics

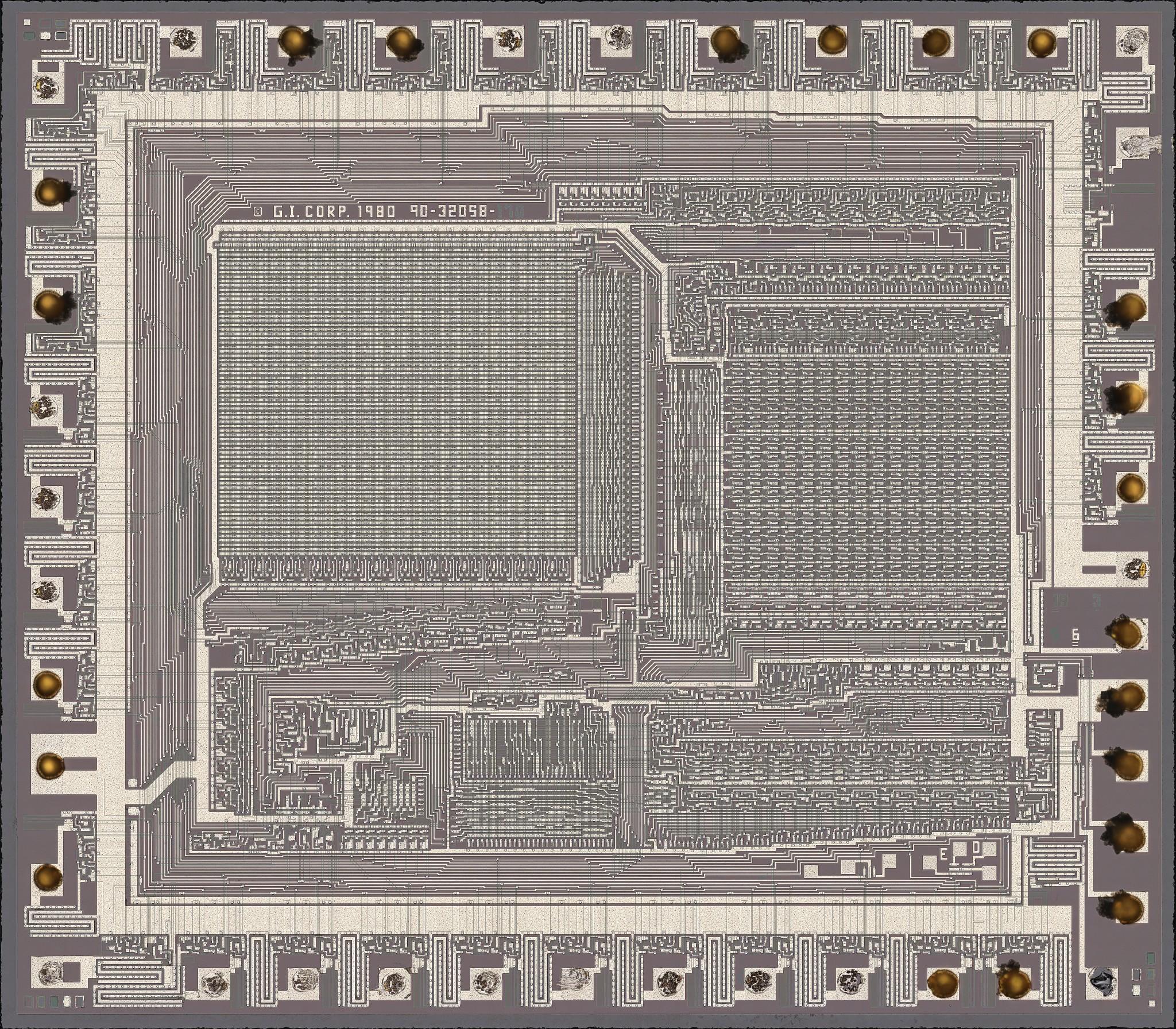

Hello! It has been a little while, but #nakeddiefriday is back in town.

Today's exhibit is an old PIC1650A. Yes, one of *the* PIC series of microcontrollers. Note it was designed by General Instrument in 1980. It was fabbed in a single metal layer, metal-gate NMOS process. The image is about 4.3x3.8 mm.

No full-res link as SP is still borked.