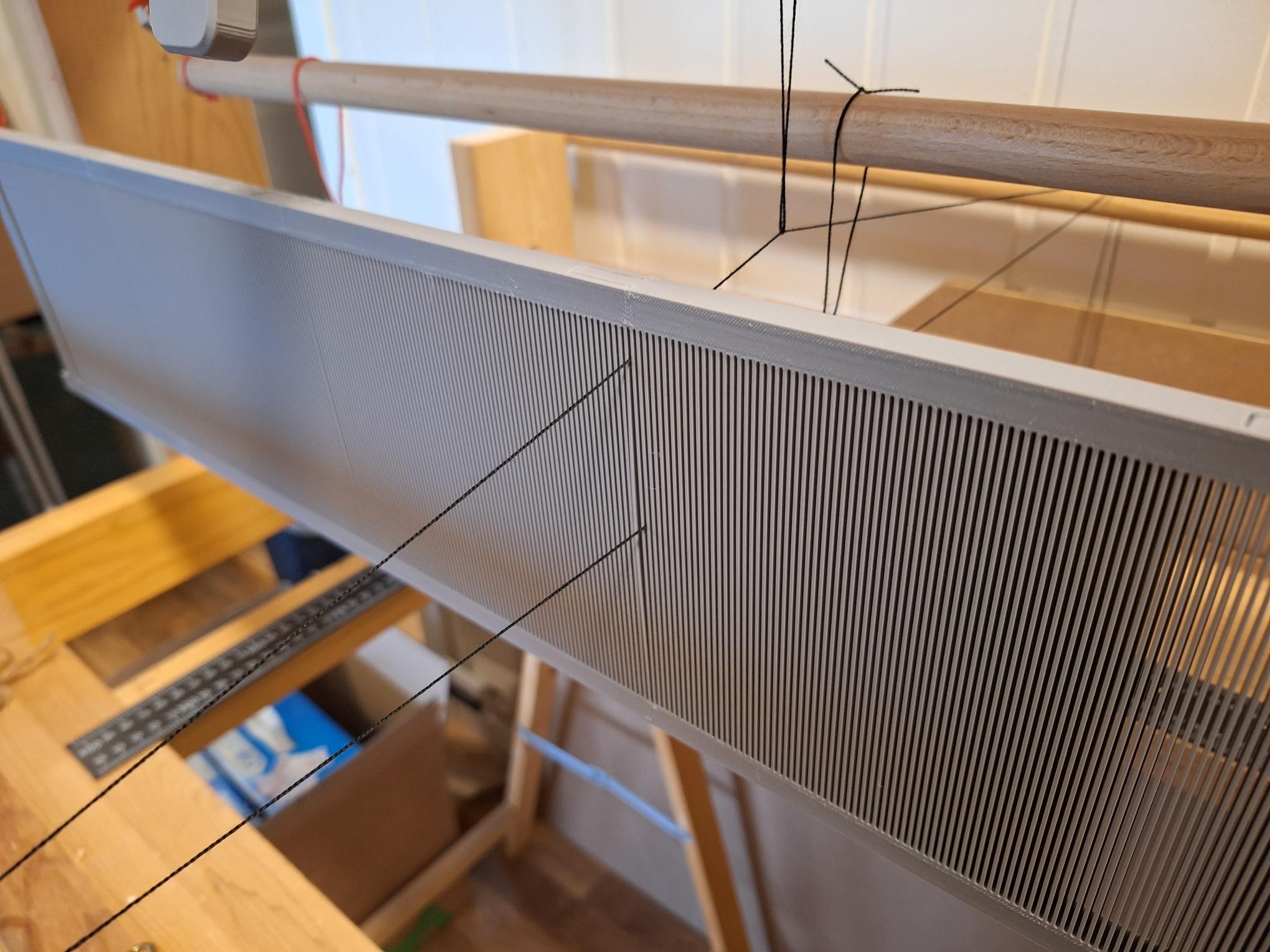

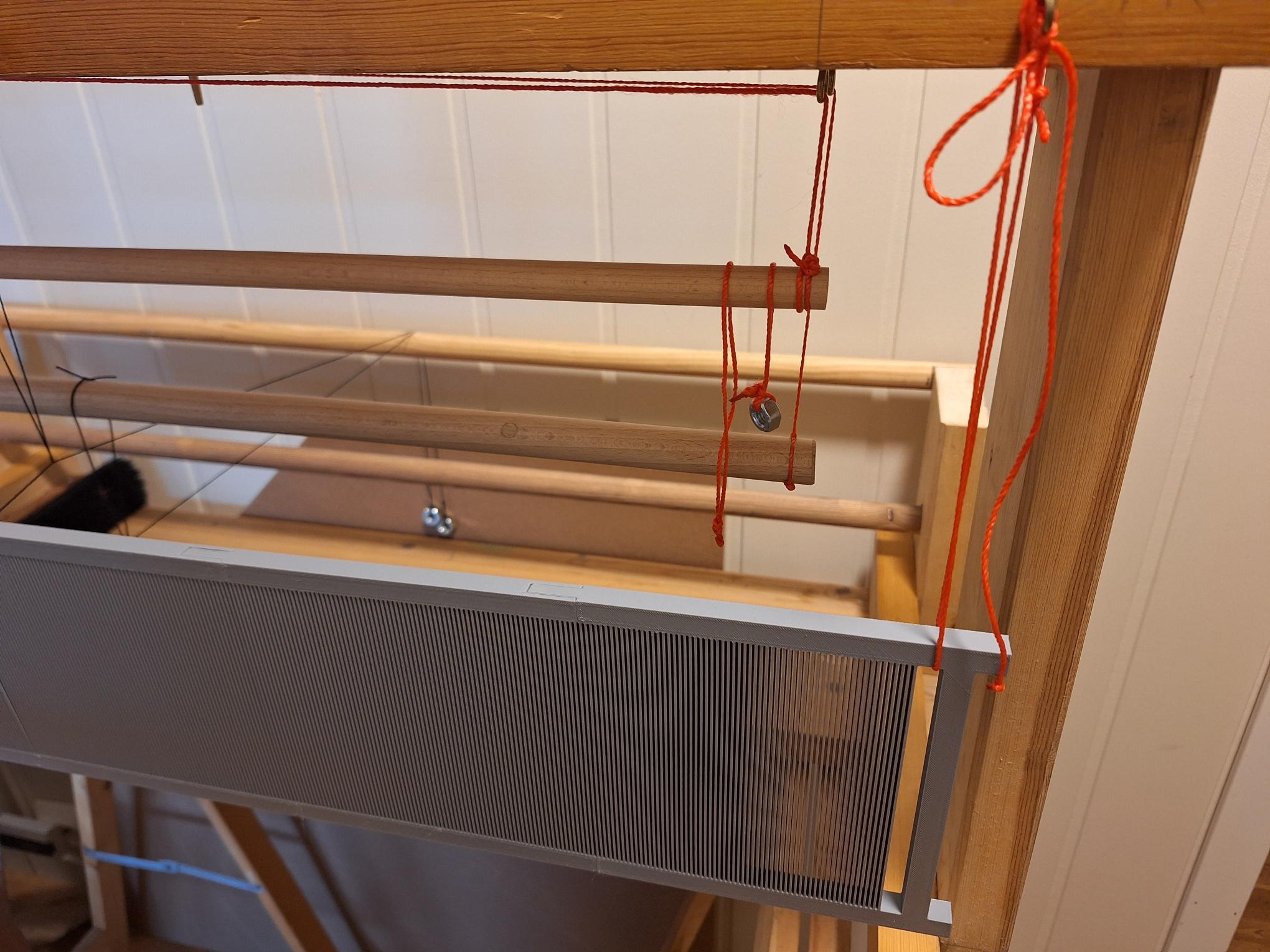

#freecadfriday my printer is currently printing the 5th of 6 segments that make up the Reed/beater of my loom. The segments were designed in @FreeCAD to slot together. One end segment, and one mid segment. So 2 ends, and 4 mids needed for my loom. More or less mids can be printed depending on size needed.

The Reed is 1mm pitch ribs and gaps. (I tried 0.5mm but it failed. The ribs stuck together in places). Hopefully 1mm will still give a nice weave. :v

The Reed is 1mm pitch ribs and gaps. (I tried 0.5mm but it failed. The ribs stuck together in places). Hopefully 1mm will still give a nice weave. :v

4 media